At Pumps of Oklahoma, we provide equipment and solutions tailored to a wide range of environmental remediation projects. Our products are designed to handle the toughest site conditions, ensuring safe, reliable, and efficient management of contaminated soil, groundwater, and air. Each solution is built to meet site-specific needs, helping clients achieve compliance, reduce costs, and move projects toward closure.

From landfill leachate pumps with chemically resistant Environmental Motors to refinery wastewater systems featuring Teflon-Fitted Pumps and radiation-resistant Nuclear Service Pumps, Pumps of Oklahoma delivers solutions for the harshest conditions. Complemented by air strippers for VOCs, PFAS-ready pumps, jet eductors, booster stations, and filtration skids, our technologies ensure efficient, resilient, and compliant performance across contaminated soil, water, and air remediation projects. Contact Us

Reliable pumping for one of the harshest liquids in the field

Landfill leachate is highly corrosive, contains debris, and varies widely in composition. Only specialized pumps can withstand such challenging conditions and keep systems running smoothly.

Our Solution:

Pumps of Oklahoma delivers Teflon-Fitted Pumps paired with robust Environmental Motors featuring continuous, chemically resistant motor leads. This advanced construction guarantees compatibility with aggressive liquids while ensuring long-term performance and insulation integrity.

For enhanced durability and versatility, pumps can be equipped with flow shrouds/cooling sleeves to maintain optimal motor temperature and protect against debris. Wheeled models are available for reliable deployment in angled or sloped landfill wells.

Applications:

Key Benefits:

Tackling aggressive waste streams at refinery and petrochemical sites

Refineries and petrochemical facilities produce some of the most challenging wastewaters—laden with hydrocarbons, acids, solvents, and brines—that quickly degrade conventional pumping systems.

Our Solution:

Pumps of Oklahoma provides Teflon‑Fitted Pumps engineered for maximum chemical resistance in refinery wastewater environments. When paired with our Environmental Motors and their continuous, chemically resistant motor leads, operators can depend on safe, reliable performance even in the harshest conditions.

Applications:

Key Benefits:

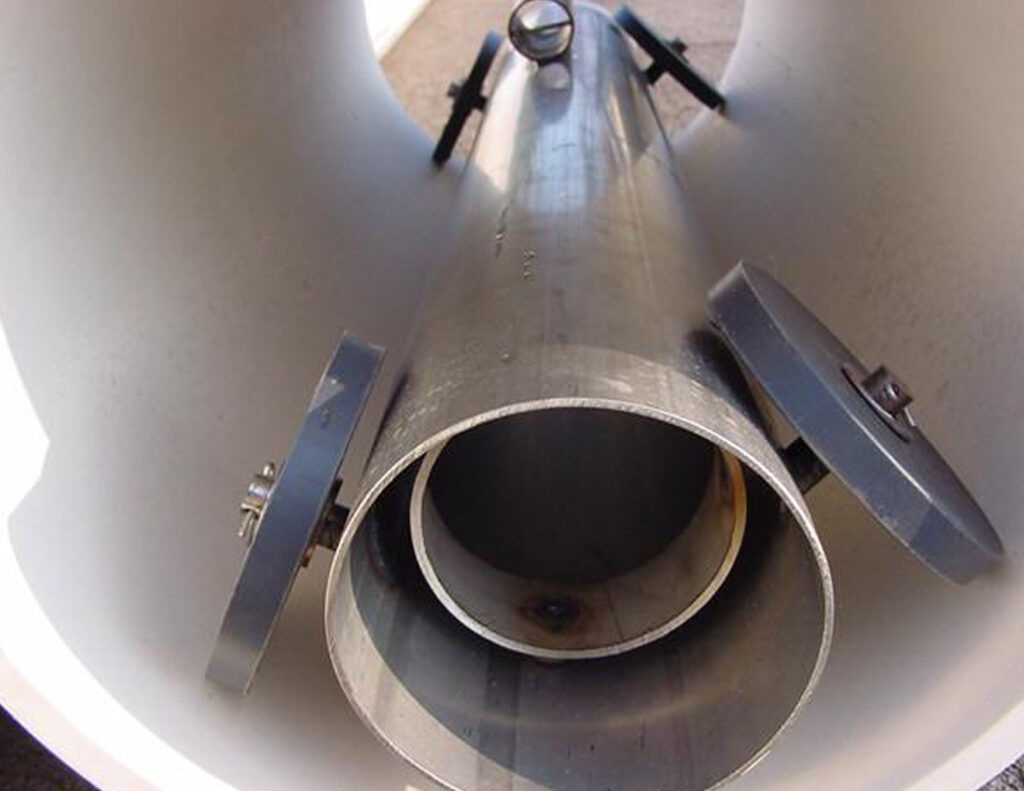

Radiation-resistant technology for reactor maintenance and servicing.

Nuclear facilities present some of the most demanding conditions for fluid handling. During reactor servicing or scheduled maintenance outages, specialized pumps are required to safely transfer or manage contaminated water while withstanding the effects of radiation.

Our Solution:

Pumps of Oklahoma provides Nuclear Service Pumps engineered with materials and designs that resist radiation damage, ensuring dependable short-term operation during critical maintenance windows. These pumps are purpose-built for controlled, temporary deployment in nuclear environments where standard industrial pumps would rapidly degrade.

Applications: Reactor maintenance and outage support, transfer of contaminated fluids during servicing, controlled use in radiation-affected zones.

Benefits: Radiation-resistant construction, proven reliability during time-sensitive operations, designed to meet strict nuclear safety and compliance requirements.

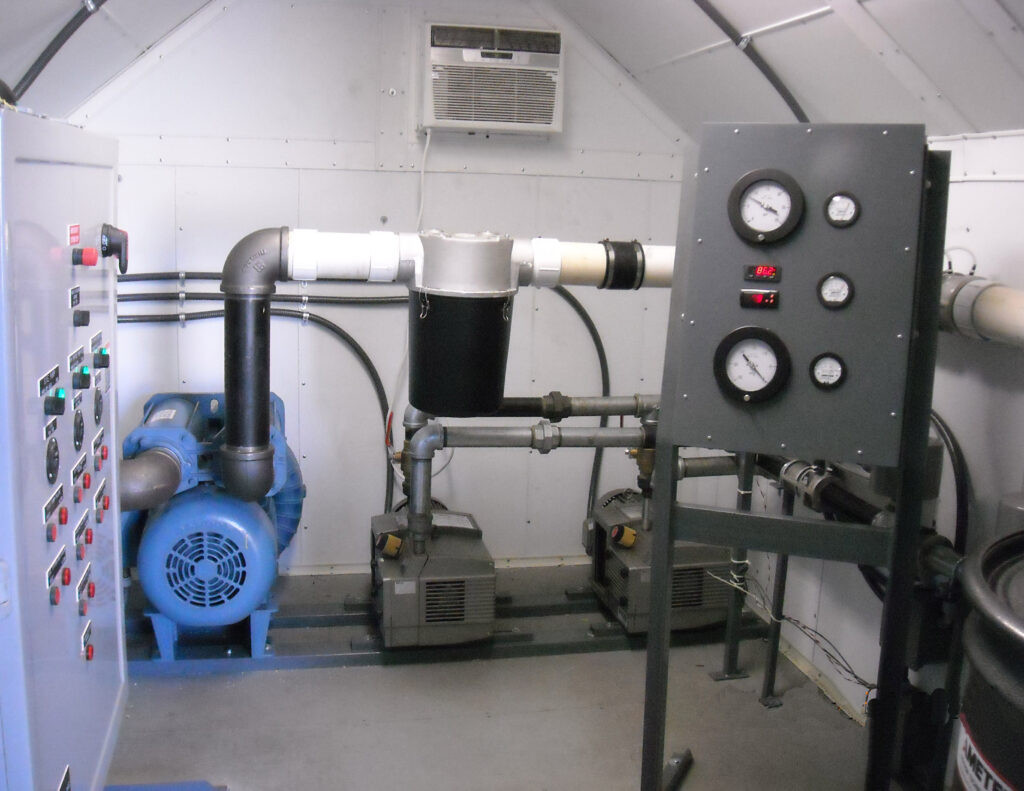

Proven technology for removing volatile organic compounds from groundwater

Volatile organic compounds (VOCs)—including benzene, TCE, and petroleum hydrocarbons—are common groundwater contaminants that require effective treatment.

Our Solution:

Pumps of Oklahoma provides air stripper systems that efficiently transfer VOCs from water to an air stream, where vapors can be safely captured and treated.

Applications:

Benefits:

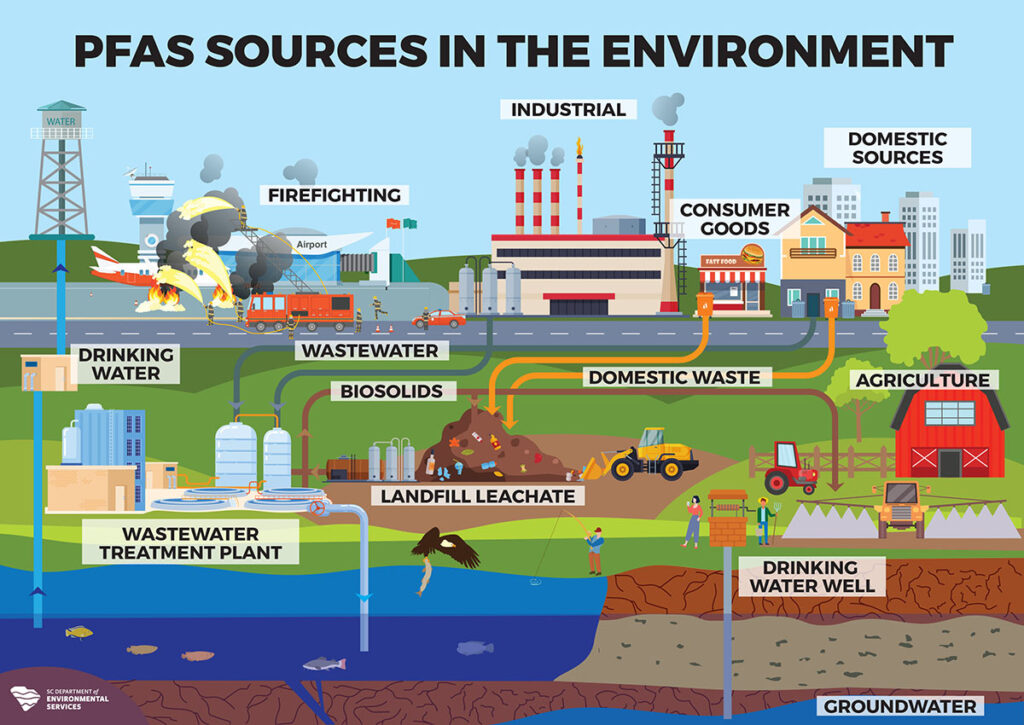

Engineered specifically for handling “forever chemicals”

Per- and polyfluoroalkyl substances (PFAS) are persistent, resistant contaminants that challenge standard pumping equipment, risking fouling or failure when exposed.

Our Solution:

Our PFAS-Compliant Pumps use non-reactive materials and specialized internal flow paths designed to minimize adsorption and prevent cross-contamination.

Applications:

Benefits:

Durable fluid and vapor recovery with no moving parts downhole

In groundwater remediation, recovering fluids and vapors in dynamic conditions with hydrocarbons requires robust systems.

Our Solution:

Jet Eductor Systems operate on the Venturi principle, creating vacuum-driven recovery without moving parts below ground, offering unmatched durability and simplicity.

Applications:

Benefits:

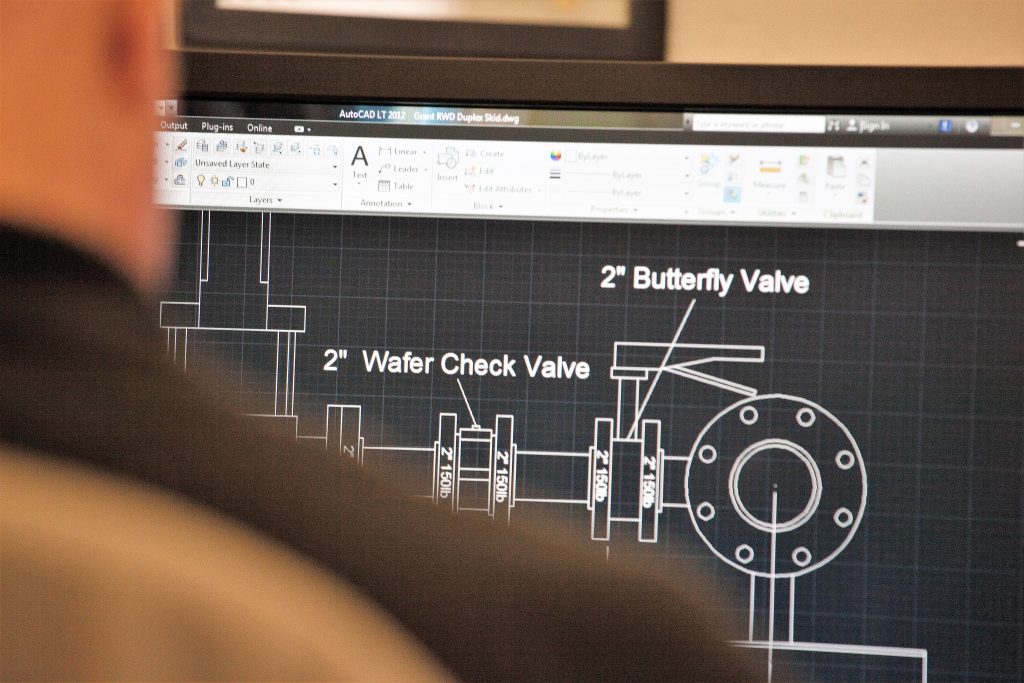

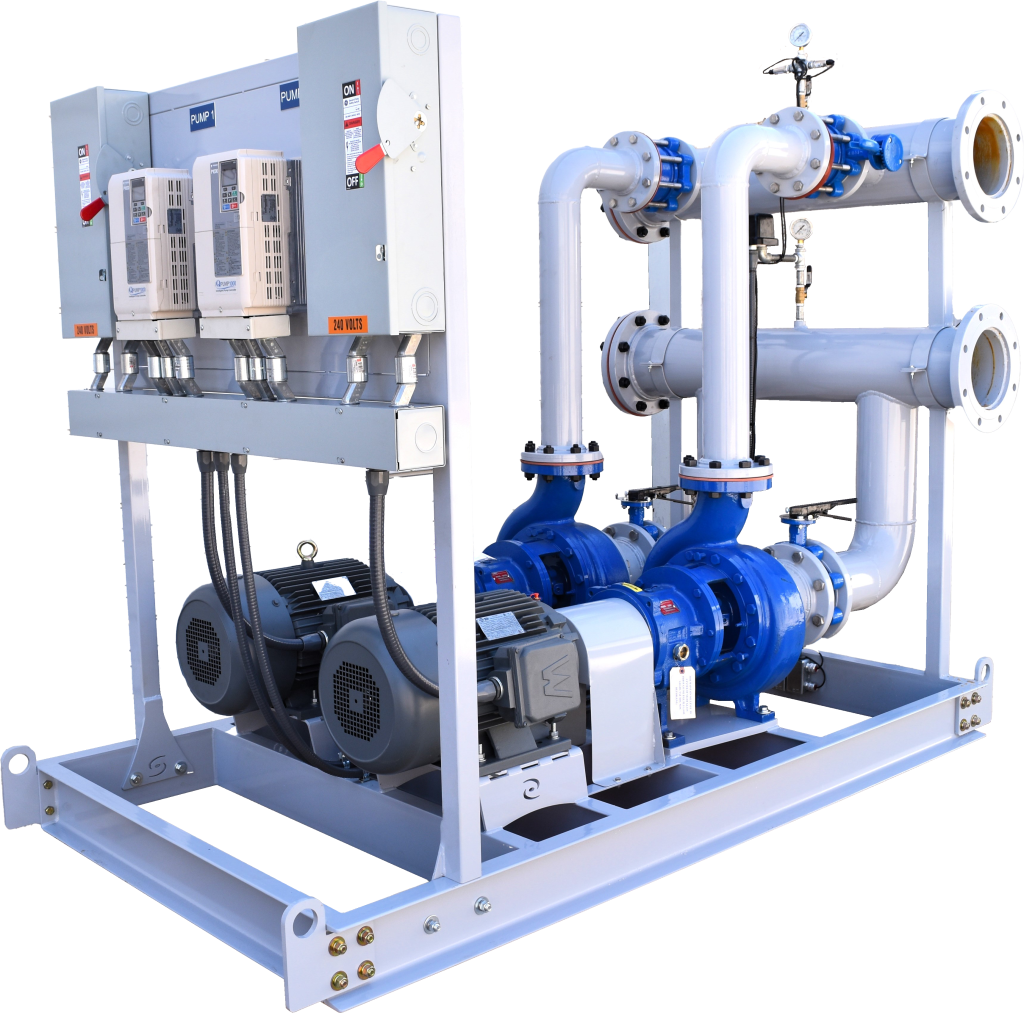

Plug-and-play pumping solutions for complex remediation projects

Remediation networks often involve multiple pumps and controls, which can slow onsite setup.

Our Solution:

Pumps of Oklahoma delivers fully assembled, skid-mounted Prepackaged Booster Stations, tested and ready for quick installation.

Applications:

Benefits:

Filtration Skids

Protection for treatment systems against solids and debris

Water with high suspended solids damages pumps, clogs media, and stresses wastewater systems.

Our Solution:

Filtration Skids configured with bags, cartridges, or media filters remove particulates before sensitive treatment processes.

Applications:

Benefits:

What are you looking for?